Replacing carbon rods with sharpened and flat face carbon rods:

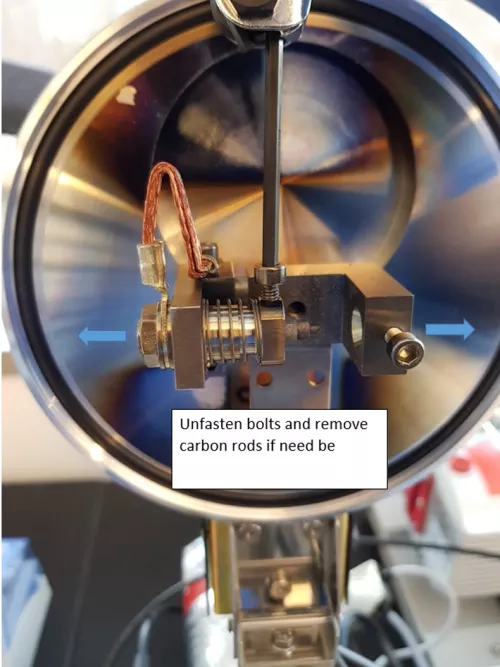

-Remove glass bell jar and unscrew the two bolts holding the carbon rods and slide the carbon rods out

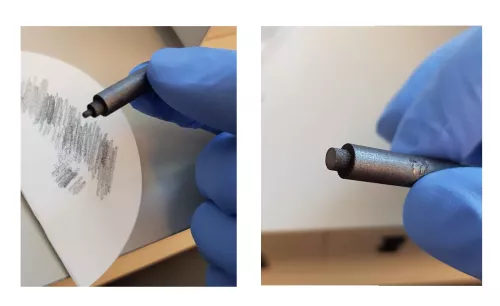

Carbon rods: one side sharpened (smaller diameter tip) one side flattened, both ends should be polished and flattened to optimize contact

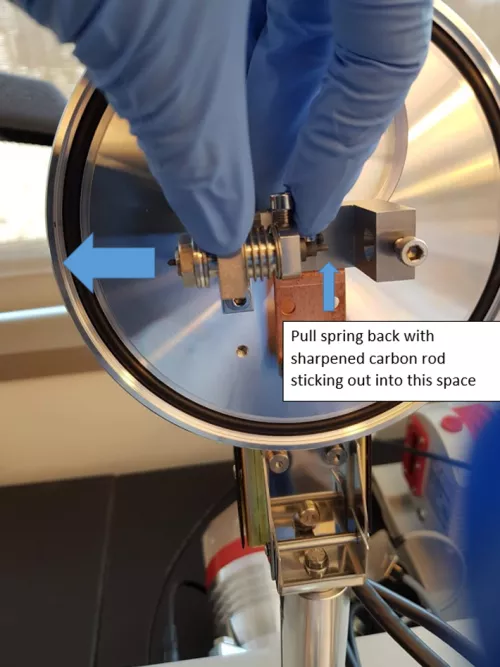

-Replace the sharpened carbon rods on the two sides of the heating element: with one carbon rod in place on the left side, fasten left bolt to secure

-After left bolt has been fastened, pull back the left side spring and slide in the flattened carbon rod on the right side to contact the sharpened rod, secure the right side rod in this position. Resulting is the spring forcing the sharpened rod against the flattened rod.

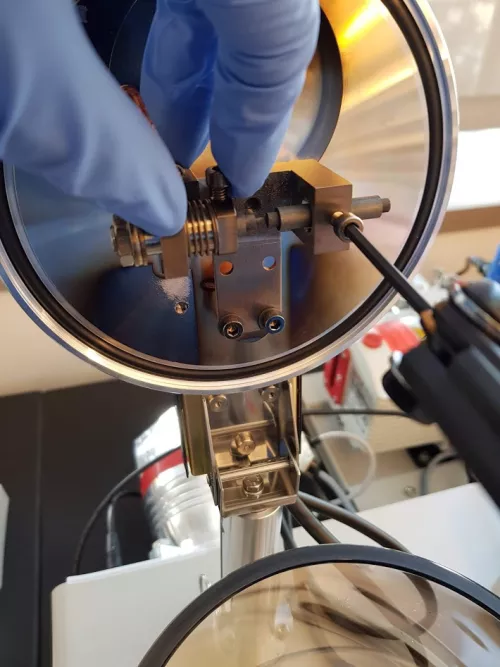

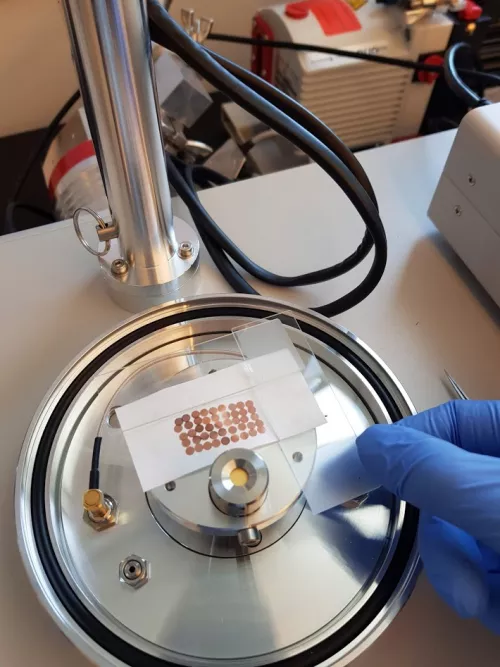

-Place amyl acetate coated copper grids on metal platform and use weights to flatten the whatman paper support

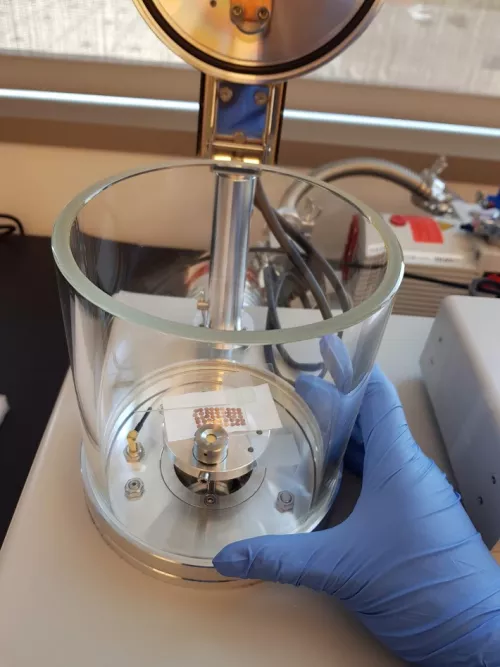

-Replace bell jar and adjust lid to seal the top of the jar chamber.

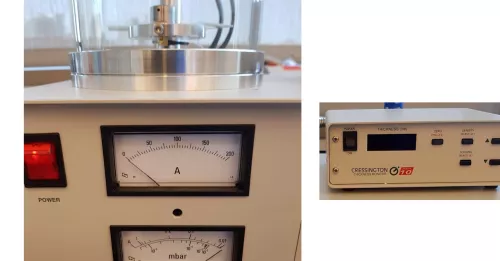

-Turn on power to 208carbon evaporator unit. vacuum will immediately begin pumping down the chamber.

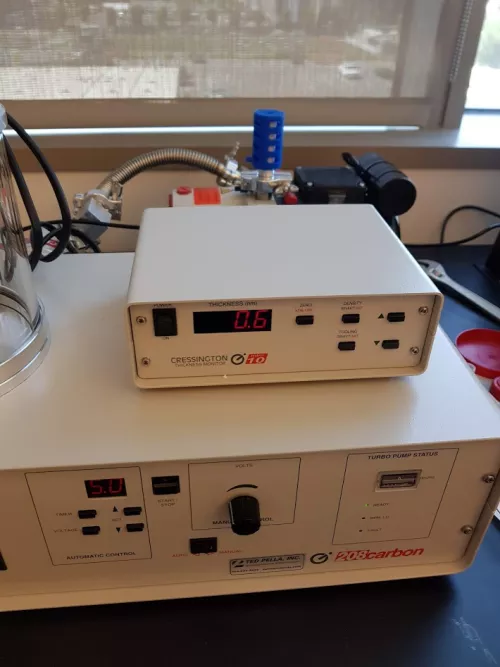

(optional: turn on power to thickness monitor, check to see that reading is '0' after powering on (not 'err')

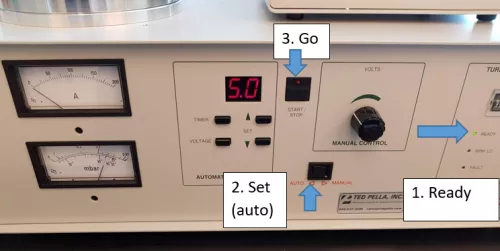

-Once the pressure reaches 0.01 mbar, the needle will jump and start moving left until it reaches about 10^-3 to 10^-4 mbar, around this time the ready light on the 208carbon unit should light up green

-The switch between manual and auto mode should be set to user preference. The auto method set for 5 seconds at 4 volts should be sufficient for achieving ~0.5 to 0.8 nm thickness indicated by the thickness monitor

-Switch off power and wait for pressure to equilibrate. The heating element and carbon rods will be extremely hot so if possible wait about 30 minutes for pressure and temperature to equilibrate and carefully remove the bell jar and grids. Reassemble unit after retrieval.

-If pressure does not equilibrate there is a pressure release knob that can be unscrewed on the back of the turbo pump. Make sure to refasten it after pressure has been released. If unsure, just wait for pressure to increase back, don't loosen screws to vacuum clamps/seals